A centrifuge is a crucial scientific device that uses centrifugal force to separate substances based on density, essential in fields like chemistry, biochemistry, and molecular biology. It comes in low, high, and ultra-speed variants, with rotational speed and capacity being key factors. Adhering to strict safety procedures is imperative during operation.

The article will introduce centrifuges from the following points:

Working Theory Of Centrifuge Machine

Classification of Centrifuge Machine

Components of Centrifuge Machine

Main Technical Parameters and Performance Indices of Centrifuges

Applications and Maintenance of Centrifuges

Common Centrifuge Failures and Troubleshooting Methods

Working Theory Of Centrifuge Machine

General Principle

The working principle of a centrifuge is based on the application of centrifugal force.

The centrifuge spins at high speed, causing substances of different densities or particle sizes in a mixture to separate. The denser or larger particles are forced to the outer edge, while the lighter or smaller ones remain closer to the center.

This principle is widely used in various fields such as medicine, science, and industry.

Specific Methods

l Differential Velocity Centrifugation Method

This method utilizes the differences in the sedimentation rates of different particles in a centrifugal force field. Under the same centrifugation conditions, by continuously increasing the relative centrifugal force, particles of different sizes and shapes in a non-uniform mixture are precipitated step by step. It is mainly used for the separation of general and special samples, such as organelles and viruses.

l Isodensity Centrifugation Method

The sample undergoes centrifugal precipitation or sedimentation equilibrium in a certain inert gradient medium. Under the action of a certain centrifugal force, the particles are distributed to certain specific positions in the gradient liquid, resulting in the separation of different zones.

Classification of Centrifuge Machine

According to Purpose: Preparation type, analytical type, and dual-purpose type for both preparation and analysis

According to Speed: low-speed, high-speed, ultracentrifuges, etc.

According to Structure: It can be divided into bench-top type, multi-tube micro type, cell smear type, blood washing type, high-speed refrigerated type, large-capacity low-speed refrigerated type, bench-top low-speed automatic balance centrifuge, etc.

Types of Centrifuges

Low-speed centrifuge

These are frequently used in laboratories for routine particle sorting operated at a maximum speed of 4000-5000 rpm. There are few instances of temperature regulation and often operated at room temperature. These centrifuges employ swinging bucket and fixed-angle rotor types, used for separating plasma and serum, as well as components like cerebrospinal fluid, pleural and peritoneal fluids, and urine.

High-speed centrifuge

It can work at somewhat faster rates ranging between 15,000 and 30,000 revolutions per minute, containing a device for regulating both the temperature and speed of the operation for the critical analysis of delicate biological molecules. These centrifuges employ three rotors: fixed angle, swinging bucket, and vertical. They are used for DNA and RNA purification, subcellular fractionation, and isolating cellular components like mitochondria.

Ultracentrifuge

It is a highly developed and sophisticated centrifuge that can separate tiny molecules that conventional centrifuges can’t separate at a fast rate. Ultracentrifuge rotor speeds can range from 60,000 to 150,000 rpm. They run samples in groups or as continuous flow systems and are larger. Ultracentrifuges are indispensable in the realm of molecular biology and biochemistry for the purification of nucleic acids and proteins.

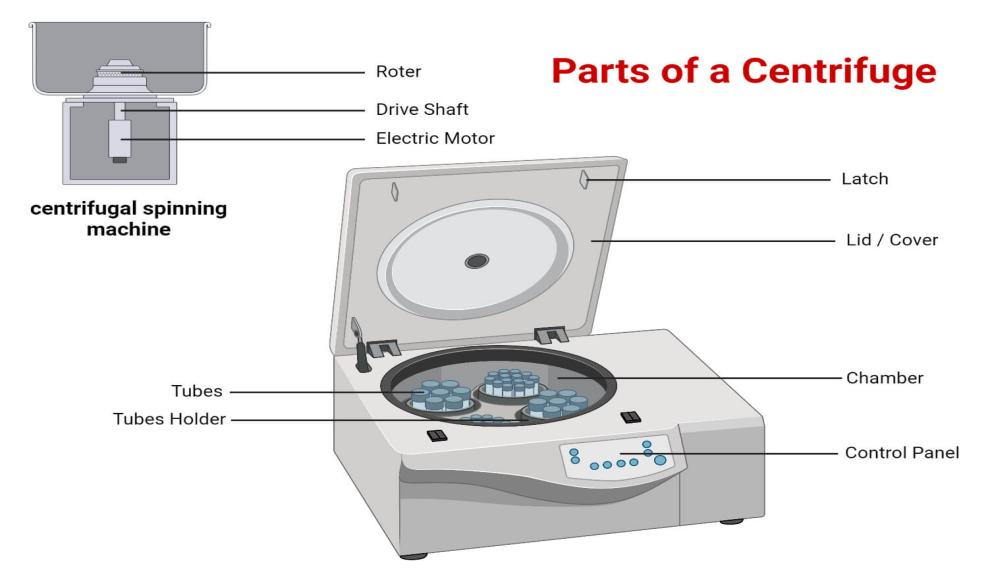

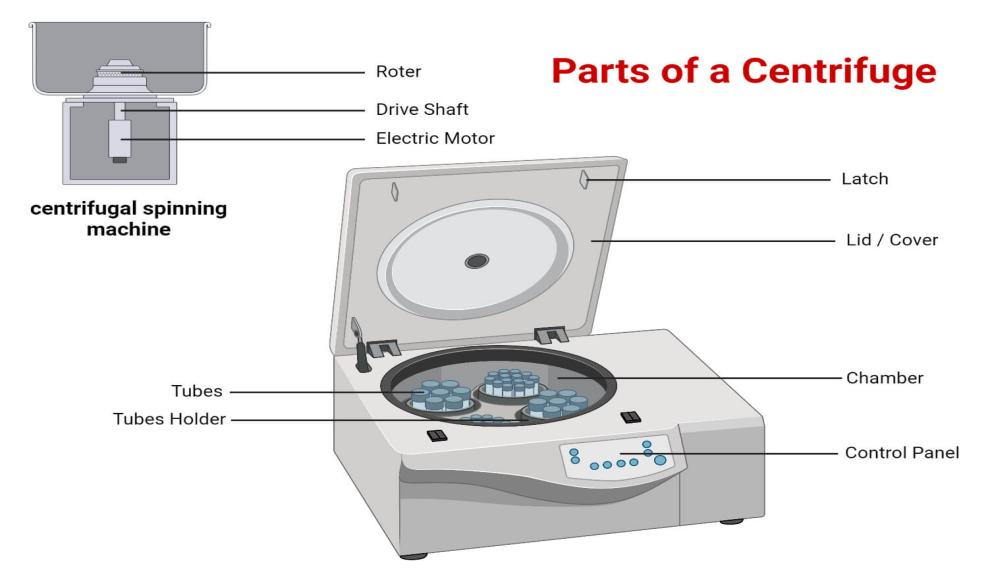

Components of Centrifuge Machine

The introduction of rotor

The rotor is the core component of a centrifuge used for separating samples, and its speed depends on the material and strength of the rotor. Low-speed centrifuges typically use strong yet lightweight super-hard aluminum alloys, while ultracentrifuges use titanium alloys. Generally, for centrifuges of the same type, rotors that are lighter and have smaller capacities spin at higher speeds, whereas heavier rotors spin at lower speeds. Centrifuges often have various rotor shapes, each reflecting different centrifugal force fields and sedimentation distances. Proper selection of rotors based on separation requirements is crucial in practical applications.

Common Types of rotors

Fixed angle rotors: These rotors hold the tubes at an angle of 14 to 40° to the vertical such that particles travel a short distance while moving radially outwards and are used in differential centrifugation.

Swinging bucket rotors: These rotors, along with the centrifuge tubes, swing out to a horizontal position during the time of acceleration such that particles travel a longer distance, thereby facilitating easier separation of supernatant from the pellet. These types of motors are employed in density gradient centrifugation.

Vertical rotors: These hold the tubes vertically, i.e., parallel to the motor axis, and the particles move shorter distances with shorter periods for separation. It is used for isopycnic and density gradient separation.

Main Technical Parameters and Performance Indices of Centrifuges

1. Maximum Speed: The highest rotational speed achievable by the centrifuge rotor, measured in rpm.

2. Maximum Centrifugal Force: The maximum relative centrifugal force (RCF) generated by the centrifuge, measured in “g”.

3. Maximum Capacity: The maximum sample volume that can be processed in one centrifugation cycle, typically represented as “m×n”. (Here, “m”denotes the maximum number of centrifuge tubes accommodated at once, and “n” represents the maximum sample volume that can be separated in two centrifuge tubes, measured in “ml”.)

4. Speed Range (Speed Setting Range): The adjustable range of rotor speeds on the centrifuge.

5. Temperature Control Range: The range of sample temperatures that can be controlled during centrifuge operation.

6. Operating Voltage: The voltage required for the centrifuge to operate.

7. Power Consumption: Typically refers to the rated power of the centrifuge motor.

Applications and Maintenance of Centrifuges

Due to the high rotational speed and the substantial centrifugal force generated by centrifuges, serious accidents may occur if they are utilized improperly or lack regular inspection and maintenance. Therefore, the operation procedures and maintenance must be strictly adhered to during use.

1. Keep Balance: centrifuge tubes and their contents must bebalanced in advance and placed symmetrically. An odd number of tubes must never be loaded in the rotor to ensure the load is evenly distributed around the rotor.

2. Load Proper Solution: open centrifuge should not be loaded with excessive solution to prevent it from being flung out during centrifugation, causing rotor imbalance, rust or corrosion.

3. Keep Observation: during the centrifugation process, the instruments on the centrifuge, should be constantly observed to determine if they are functioning properly. If any abnormal occur, the machine should be halted immediately for inspection and the malfunctions should be promptly eliminated. It must not continue to operate until the root cause is identified.

4. Inspection Before each using: the rotor apertures should be strictly inspected for any foreign objects and dirt to maintain equilibrium. The rotor should also be checked for any signs of damage or wear.

5. Pay attention to plastic tubes: control the usage frequency of plastic centrifuge tubes and check the matching specifications. Different types of centrifuge tubes have different material properties and maximum speed limits.

6. Pre-cooling: when centrifuging samples at low temperatures, pre-cooling for a certain period of time is necessary.

7. Regular maintenance: The horizontality of the main body of the centrifuge should be calibrated once every three months. When not in regular use, it should be started at low speed for 1 to 2 times per month, each time for 0.5 hours.

Common Centrifuge Failures and Troubleshooting Methods

Common Failures

1. Motor not running

2. Motor fails to reach rated speed

3. Rotor damage

4. Freezer failure to start or poor cooling performance

5. Excessive vibration or unusual noise from the centrifuge body

Troubleshooting Methods

For Motor not running

1. Main power indicator light not on: Check if the fuse is blown, and ensure good contact between the power cord, plug, and socket.

2. Main power indicator light on but motor cannot start:

(1) Check if the band switch or porcelain variable resistor is damaged, or if their connecting wires are disconnected.

(2) Check for disconnected or internally short-circuited connections in the magnetic field coil.

3. Check vacuum pump gauge and oil pressure indicator values.

For Motor failing to reach rated speed

1. Drive shaft damage or obstruction. It should be cleaned and replaced promptly.

2. Clean the commutator and brushes to ensure good contact, or replace them.

3. Check for any short circuits or open circuits in the rotor coil windings.

For Rotor Damage

1. Rotor heads can rupture centrifuge tubes due to factors such as metal fatigue, overspeed, overstress, chemical corrosion, improper selection, unbalanced use during operation, and temperature control failure, leading to sample leakage and rotor head damage. The electric motor has upper and lower bearings that require periodic lubrication (every six months or annually).

2. Operators must be proficient in operational procedures, correctly select suitable centrifuge tubes and rotor heads, and adhere to safety factors and warranty periods for rotor head usage.

For Freezer Failure to Start or Poor Cooling Performance

1. Power failure, check the power cord and fuses separately.

2. Low voltage triggers safety devices preventing the freezer from starting.

3. When the power voltage drops to 180V to 190V, the freezer cannot start, affecting cooling efficiency.

4. Poor ventilation performance can also affect cooling efficiency.

For Excessive vibration or unusual noise from the centrifuge body

1. The weight of the centrifuge tubes is unbalanced, and they are placed asymmetrically.

2. There are foreign objects in the rotor holes, the load is unbalanced, or unqualified tube sleeves are used.

3. The fixing nut at the upper end of the rotor shaft is loose, causing friction or bending of the rotor shaft.

4. The motor rotor not being in the center of the magnetic field will generate noise.

5. The fixing screws of the damping springs on the base are loose, or one of the springs is broken.

6. The rotor itself is damaged.